This is a QRK Model 12C turntable used in radio broadcast stations. This idler wheel turntable operates in only in the single-play mode. The turntable has three standard speeds: 33 1/3, 45, and 78 rpm, selected by a lever on the front of the turntable. The key feature of this turntable is a fast start to correct speed when the turn table is turned on using the toggle switch on the lower left. An indicator light on the lower right iluminates when the turntable is turned on. When used in a radio station, the disk jockey will lift the tonearm and place the stylus at the place in the record where he wants the sound to begin (usually at the beginning of a track). With the turntable off, he then can backcue the turntable while listening off air such that the track will begin immediately when the turntable is turned on.

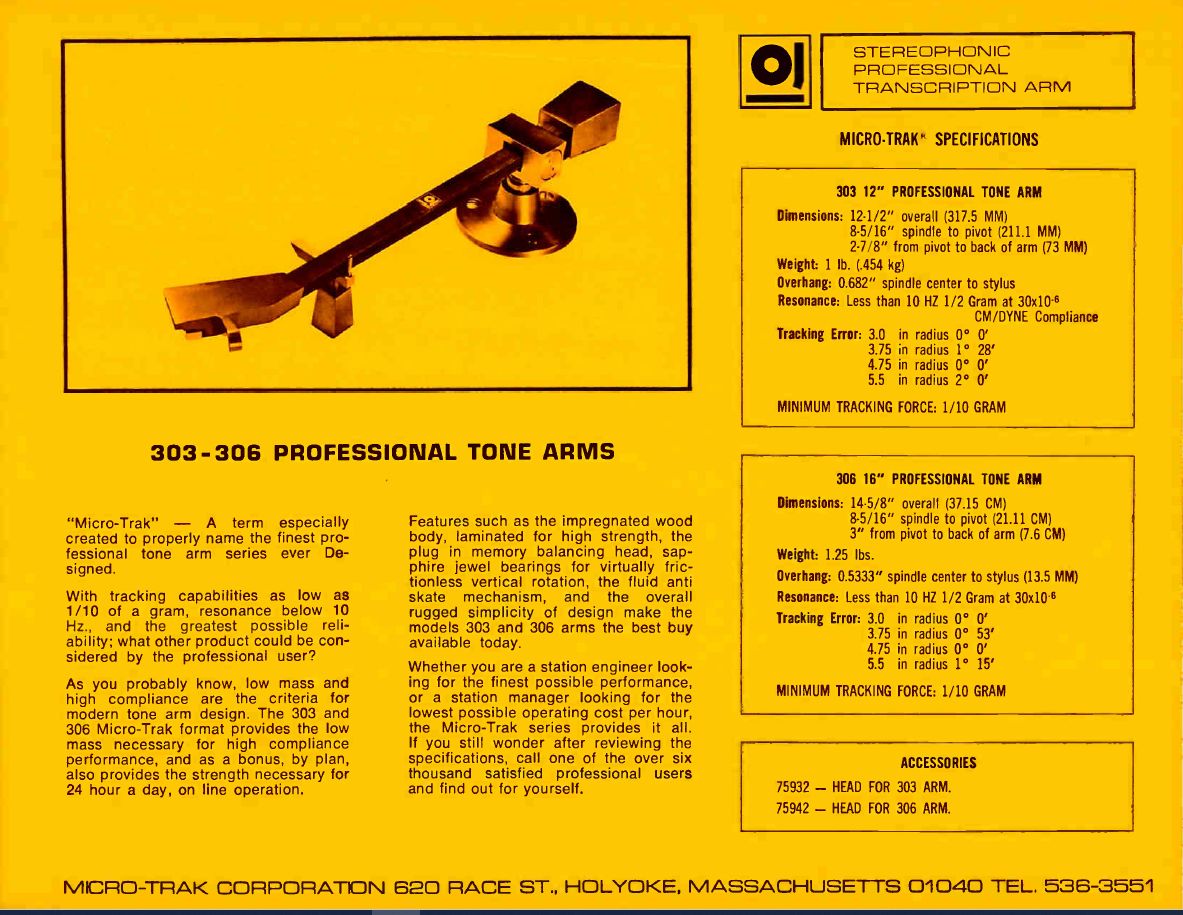

This turntable is equipped with a Micro Trak Model 303 Stereophonic Professional Transcription tonearm. The specifications for this tonearm taken from a Micro Trak brochure is shown below.

The only adjustment for the tonearm is the placement of the counterweight at the rear of the tonearm. With the phono cartridge in place, I used a tension gauge to measure the stylus force on the gauge while adjusting the counterweight position to produce the stylus force recommended by the cartridge manufacturer. There is not adjustment for anti-skating.

This turntable came with a Shure M44E phono cartridge installed shown below. The tonearm head containing the cartidge can be removed from the wooden tonearm by gently pulling it out.

The stylus was missing when I received the turnable, but replacements can be readily obtained.

A common problem with these turntables occurs when the motor/idler wheel mechanism is left engaged with the platter. After a period of time, an indention will be imparted in the rubber of the idler wheel. The idler wheel in this turntable had this problem. The indention makes a audible "thump" when playing a record. The idler wheel removed from the turntable is shown below. The indention is slightly visible in the hard rubber at the bottom of the picture next to the ruler.

The rubber had also hardened over time and increases rumble in the audio. I sent the idler wheel off to be restored.

The platter is easily removed from the turntable. One has to reach underneath and push it up with fingers through holes in the frame. The long spindle of the platter inserts into a "well" that is filled with oil. At the bottom of the well is a single ball bearing on which the platter spindle rests. I used 3-IN-ONE Motor Oil to fill the well. Although the well is long in length, the spindle takes up most of the volume and as such, not much oil is required.

In a radio station studio, the turntable typically is placed in the top of a desk or console, often one turntable on either side of the disk jockey. For my application I made a plinth out of wood on which to mount the turntable. The motor extends a significant amount below the turntable and as such, the pinth is high as can be seen in the photo above. I brought the ac power cord and audio cables out the rear of the plinth as shown below.

I also replaced the felt on the turntable platter. The original felt was still in good shape, but its perimeter and cutout in the center was an irregular shape. I made a circular template and used a hobby knife to cut out the felt from a larger felt piece. I used Aleene's Original Tacky Glue to fasten the felt to the platter.

The platter has a built-in short spindle for playing 33 1/3 and 78 records. Those records rest on the higher surfaces of the platter. The platter also has a built-in wide spinde to play 45 records and a 45 record rests on the lower surface of the platter.

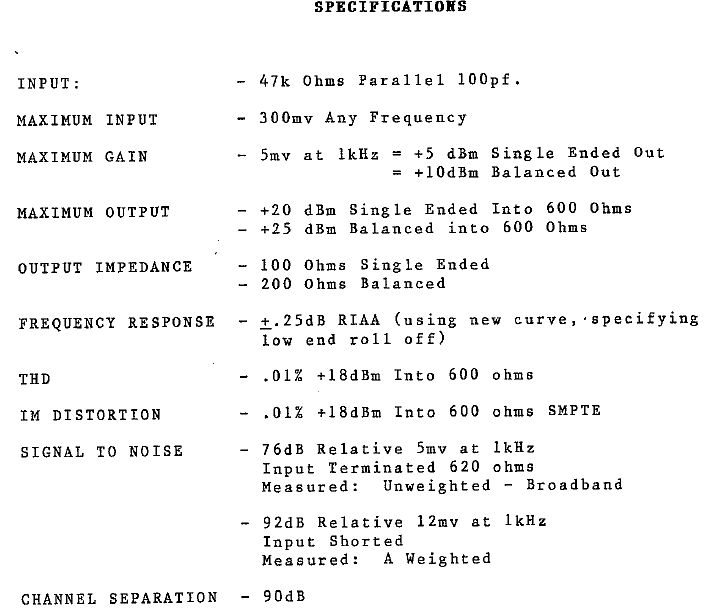

I have an Audio-Metrics Model PA-1 broadcast solid-state phonograph pre-amplifier manufactured by Radio Systems of Edgemont, PA. Pictures of the pre-amplifier and its specifications are shown below.